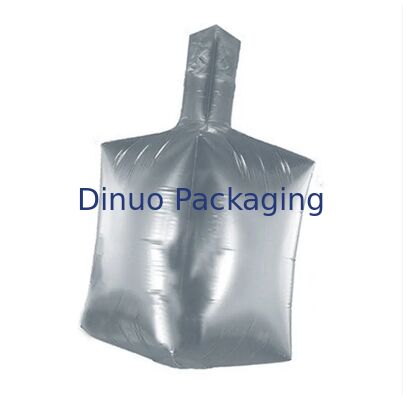

Moisture Proof Multi Layer Structure Inner Bag Of Container Bag For Chemical Powder Food Solids Storage

Based on the explosive growth of raw material products such as lithium batteries, degradable plastic particles, nylon and so on, we quickly laid out solid soft packaging business in inner bag of container bags and introduced the first full-servo high-speed automatic production line in China to improve production efficiency. At the same time, we continue to improve the characteristics of different film materials, strictly control the magnetic ad non-magnetic physical standards of the workshop, to make the inner bag is more anti-oxidation, moisture resistance, corrosion resistance, pollution-free, and give the container bag a wider range of safer material performance and application.

| Product Type |

Inner Bag of Container Bag/Ton Bag |

| Material Structure |

PET/AL/PA/PE;PE/AL/PA/PE; PET/VMPET/PE |

| Core Features |

Anti-oxidation, moisture/corrosion resistance, anti-kneading, high barrier, puncture resistance, lightproof, soft texture, stable oxygen permeability, wear resistance, high tensile strength |

| Mechanical Properties |

Tensile force ≥30-100 N/15mm, puncture resistance ≥3-12 N, elongation at break ≥200%, excellent anti-kneading performance |

| Application |

Lithium battery cathode/anode materials, degradable plastic particles, food powder/solids, chemical intermediates/powders, daily chemical intermediates, nylon particles |

| Production |

Full high-speed automatic production line; non-magnetic physical workshop standard; pollution-free production process |

| Product name |

Structural composition |

Product feature |

|

Aluminum foil inner bag

The surface material is PET

|

|

It has the characteristics of anti-rubbing, not easy to break, soft, stable overall oxygen permeability and so on |

|

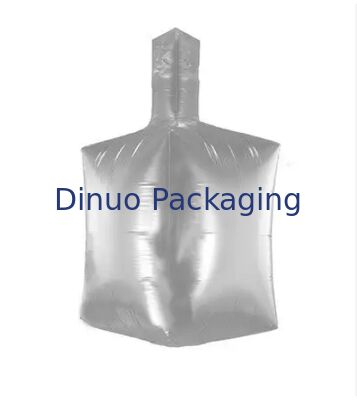

Aluminum foil inner bag

The surface material is PET

|

|

The surface material is 100% PE, it has the advantage of aluminum foil inner bag but more soft. |

|

VMPET inner bag

The surface material is PET

|

|

It has high tensile strength, high barrier, puncture resistance, kneading resistance and many other mechanical properties. |

| Inspection item |

Standard requirement |

| PET/AL/NY/CPE |

CPE/AL/NY/CPE |

PET/NY/CPE |

PET/VMPET/CPE |

CPE/CPE |

VMPE/CPE |

| Pulling strength(N/15mm) |

≥100 |

≥80 |

≥80 |

≥80 |

≥30 |

≥30 |

| Breaking Elongation(%) |

≥80 |

≥80 |

≥80 |

≥80 |

≥300 |

≥300 |

| Resistant to pendulum impact (J) |

≥2.0 |

≥2.0 |

≥2.0 |

≥1.0 |

≥1.0 |

| Oxygen transmittance cm3/(㎡.24h.0.1mpa) |

≤0.5 |

≤100 |

≤2 |

- |

≤100 |

| Water vapor transmittance g/(㎡.24h) |

≤0.5 |

≤10 |

≤2 |

≤15 |

≤2 |

| Combined strength(N/15mm) |

PET/AL ≥2.5 |

PE/AL ≥2.5 |

PET/NY ≥2.5 |

PET/NY ≥2.5 |

CPE/CPE ≥2.5 |

VMPE/CPE ≥2.0 |

| AL/NY ≥3.5 |

AL/NY ≥3.5 |

NY/CPE ≥5 |

NY/CPE ≥5 |

- |

- |

| NY/CPE ≥5 |

NY/CPE ≥5 |

- |

- |

- |

- |

| Heat sealing strength(N/15mm) |

≥100 |

≥80 |

≥80 |

≥80 |

≥80 |

≥80 |

| Puncture strength(N national standard) |

≥12 |

≥8 |

≥10 |

≥10 |

≥3 |

≥3 |

1. Ultra-high Barrier Protection

This container bag inner bag adopts PET/AL/PA/PE and VMPET composite structures, which achieves excellent barrier effects against oxygen, moisture and light. It can effectively isolate external air and moisture, preventing the deterioration of lithium battery materials, food powder and other sensitive materials during storage and transportation.

2. Robust Mechanical Durability

With a tensile force of ≥30-100 N/15mm and puncture resistance of ≥3-12 N, the inner bag has strong anti-kneading and wear resistance. It can withstand the extrusion, collision and repeated handling in industrial transportation, and is not easy to tear or leak, ensuring the safety of packaged materials.

3. Versatile Material Structure Options

We provide multiple material structures including PET/AL/PA/PE, PE/AL/PA/PE and PET/VMPET/PE, as well as single-layer PE structure. Different structures can be selected according to the characteristics of materials like lithium battery raw materials, food solids and chemical intermediates.

4. Broad Industrial Applicability

The inner bag is widely used in packaging lithium battery cathode and anode materials, degradable plastic particles, food powder, chemical intermediates and daily chemical raw materials. It perfectly meets the packaging demands of new energy, food processing, chemical manufacturing and daily chemical industries.

5. Flexible Customization Service

We support personalized customization of size, thickness and material structure for the inner bag, and also offer surface material customization and logo printing service. This allows the product to be tailored to the specific usage scenarios and brand needs of customers.

6. High-standard Production Process

The inner bags are produced by a full high-speed automatic production line, and the workshop complies with non-magnetic physical standards with a pollution-free production process. This ensures the consistent quality and high performance of each product, meeting the strict requirements of industrial production.

The application of ton bag:

All suitable for the ton bag packaging industry, like new energy lithium battery industry, chemical raw materials, pharmaceutical raw materials, plastic raw materials, food additives, feed additives, metallurgical powder, ore powder, sand and gravel, refractory materials and so on, the container bags mainly pack block, granular or powdered items, and the physical density and looseness of the contents also have a significantly different impact on the overall result.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!